Borescope Inspections

What is a borescope inspection?

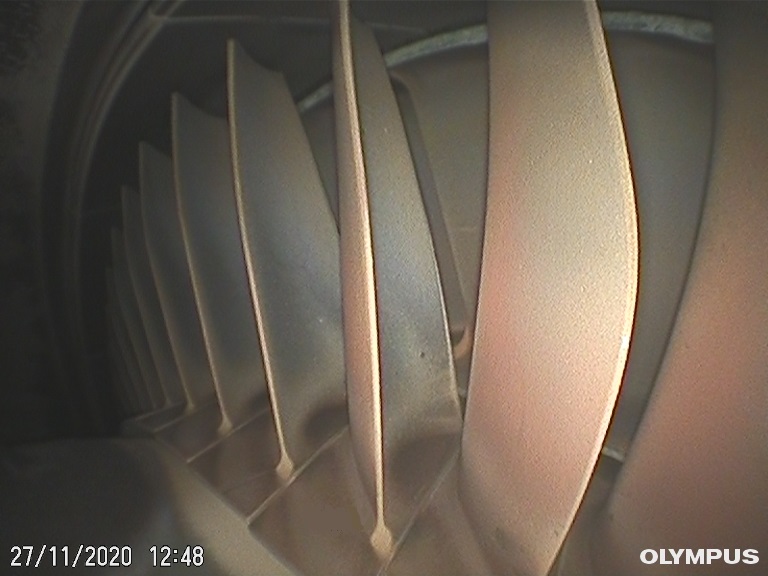

A borescope inspection is a non-destructive inspection of the accessible internals of a turbine engine which are performed to obtain an impression of the condition of certain areas inside the engine. When performed on a human being, the analog inspection (e.g. of the stomach) is called endoscopy.

Why borescope inspections?

Like any other machine, a turbine engine is subject to attrition and therefore requires ongoing maintenance. Significant engine maintenance, being scheduled or unscheduled, usually requires the removal of an aircraft engine.

Since it is important for almost any aircraft operator to make best use of the asset, the objective is to maximize the on-wing time in service of their turbine engine(s). To keep aircraft engines on-wing as long as possible, their internal and external condition needs to be known. Many areas inside a turbine engine are accessible with a borescope.

This is why borescope inspections play a significant role when scheduling aircraft engine maintenance events. There are also Service Bulletins and Airworthiness Directives calling for borescope inspections. Borescope inspections may also be required to determine the condition of an aircraft engine after an exceedance, an operation outside of the limits permissable or after incidents.

How to borescope-inspect an aircraft turbine engine

If the turbine engine is in service, the engine should cool down for several hours (varies by engine type and size) before the borescope inspection can be performed.

Typically, aircraft turbine engines are accessed from the front (compressor), the back (exhaust) or through ports which can be opened by qualified personal to allow the insertion of the flexible rigid borescope tube into the engine. The opposite applies to reverse flow engines such as the P&WC PT6A-Series engines.

On some engine types, specific borescope guide tubes, such as guide tube P/N PWC34910‑804 for the P&WC PW100 engine series, guide tube P/N PWC57320 for the P&WC PW150A engine or guide tubes P/N 34910-200, P/N 34910-400, P/N 34910-600 for the P&WC PT6A engine series, are required to borescope-inspect certain areas of a turbine engine.

After completing a borescope inspection, it is essential for the safety of the operation to have all borescope ports closed by qualified personal.

Where are borescope inspections performed?

An aircraft hangar is not a must to perform an engine borescope inspection. As a general rule, an engine removal is not required for a borescope inspection.

Depending on the weather, it is possible to perform borescope inspections in the field, meaning on the apron outside of a hangar, provided it is assured that no objects or fluids foreign to the aircraft turbine can enter it through a borescope port whilst the engine is being inspected.

Advantages of borescope inspection

A borescope inspection allows an individual or maintenance personal to obtain a visual impression of: the low-pressure and high-pressure compressor rotors/stators/cases, hot section, fuel nozzles, combustion chambers, HP/LP blades and vanes, exhaust cases, cavities, gears, gearboxes and more.

In case of findings during a borescope inspection, a shorter borescope inspection interval may allow to continue operating an engine instead of removing it immediately for a shop visit.

Limitations of borescope inspections

With the borescope inspection being a visual inspection, it has its limitations.

The detection of hairline cracks may be difficult or impossible based on the size of the cracks and their location. Also, there are cavities in an aircraft engine which cannot be accessed with a borescope. The condition of bearings for example may be impossible to determine with a borescope – unless there is massive bearing damage.

Kabamba Aerospace can perform measurements of length, depth and height on various surfaces inside an aircraft engine. Kabamba Aerospace can also determine categorize findings such as cracks, missing material, bulging, corrosion, erosion, foreign object damage (FOD), loss of coating, heat distress etc., it is important to mention that measurements taken with a borescope can lack accuracy.

Borescope Inspections are not intended to replace or diminish the importance of doing scheduled inspections or maintenance, but is intended to monitor the internal components of the engine to help reduce the cost of future repairs/ refurbishments.

Borescope Inspections are also limited in what is viewed at the time of inspection and image perspective(s) are larger that actual size perspective.

Cost of borescope inspections

The charges for borescope inspections can range from several hundreds to several thousand US Doller or Euros per engine, depending on the type of engine and the areas of the engine to be inspected.